Thermodynamic Database

Components (14)

Total of 14 components are included in the database as listed here:

Elements: Al, Cd, Ce, Cu, Fe, Mg, Mn, Ni, O, Pb, Si, Sn, Ti, Zn

Suggested Composition Range

The suggested composition range for each element is listed in Table 1. It should be noted that this given composition range is rather conservative. It is derived from the chemistries of the multicomponent commercial alloys that have been used to validate the current database. In the subsystems, many of these elements can be applied to a much wider composition range. In fact, some subsystems are valid in the entire composition range as given in Section Assessed Subsystems.

| Elements | Composition Range (wt.%) |

|---|---|

|

Al |

0 ~ 80 |

|

Mg |

0 ~ 40 |

|

Cu, Fe, Mn, Ni, Si |

0 ~ 10 |

|

Ce, Pb, Sn, Ti |

0 ~ 2 |

|

Cd, O |

0 ~ 0.5 |

|

Zn |

Balance |

What is new in PanZn2024

Addition of the component O.

Phases

Total of 325 phases are included in the current database. The names and thermodynamic models of some phases are given in Table 2. Information on all the other phases may be displayed through TDB viewer of Pandat™.

Assessed Subsystems

A total of 118 subsystems, including 86 binary and 32 ternary subsystems have been assessed. The modeling status is indicated by numbers. The systems with number 10 are fully assessed in the whole composition range. The higher value shows higher reliability of the system.

Binary Systems (86)

| Al-Cd(10) | Al-Ce(10) | Al-Cu(10) | Al-Fe(10) | Al-Mg(10) | Al-Mn(10) | Al-Ni(10) |

| Al-O(10) | Al-Pb(10) | Al-Si(10) | Al-Sn(10) | Al-Ti(10) | Al-Zn(10) | Cd-Ce(10) |

| Cd-Cu(10) | Cd-Fe(10) | Cd-Mg(10) | Cd-Mn(10) | Cd-Ni(10) | Cd-Pb(10) | Cd-Si(10) |

| Cd-Sn(10) | Cd-Ti(10) | Cd-Zn(10) | Ce-Cu(10) | Ce-Fe(10) | Ce-Mg(10) | Ce-Mn(10) |

| Ce-Ni(10) | Ce-O(10) | Ce-Si(10) | Ce-Ti(10) | Ce-Zn(10) | Cu-Fe(10) | Cu-Mg(10) |

| Cu-Mn(10) | Cu-Ni(10) | Cu-O(10) | Cu-Pb(10) | Cu-Si(10) | Cu-Sn(10) | Cu-Ti(10) |

| Cu-Zn(10) | Fe-Mg(10) | Fe-Mn(10) | Fe-Ni(10) | Fe-O(10) | Fe-Pb(10) | Fe-Si(10) |

| Fe-Sn(10) | Fe-Ti(10) | Fe-Zn(10) | Mg-Mn(10) | Mg-Ni(10) | Mg-O(10) | Mg-Si(10) |

| Mg-Sn(10) | Mg-Ti(10) | Mg-Zn(10) | Mn-Ni(10) | Mn-O(10) | Mn-Pb(10) | Mn-Si(10) |

| Mn-Sn(10) | Mn-Ti(10) | Mn-Zn(10) | Ni-O(10) | Ni-Pb(10) | Ni-Si(10) | Ni-Sn(10) |

| Ni-Ti(10) | Ni-Zn(10) | O-Pb(10) | O-Si(10) | O-Sn(10) | O-Ti(10) | O-Zn(5) |

| Pb-Si(10) | Pb-Sn(10) | Pb-Zn(10) | Si-Sn(10) | Si-Ti(10) | Si-Zn(10) | Sn-Ti(10) |

| Sn-Zn(10) | Ti-Zn(10) |

Ternary Systems (32)

| Al-Ce-Fe(10) | Al-Ce-Mn(10) | Al-Ce-Si(10) | Al-Ce-Zn(10) | Al-Fe-Ni(10) | Al-Fe-Si(10) |

| Al-Fe-Ti(10) | Al-Fe-Zn(10) | Al-Mg-Mn(10) | Al-Mg-Si(10) | Al-Mg-Ti(10) | Al-Mg-Zn(10) |

| Al-Mn-Ni(10) | Al-Mn-Si(10) | Al-Mn-Ti(10) | Al-Ni-Si(10) | Al-Ni-Ti(10) | Al-Si-Ti(10) |

| Al-Si-Zn(10) | Fe-Mg-Mn(10) | Fe-Mg-Si(10) | Fe-Mn-Si(10) | Fe-Mn-Ti(10) | Fe-Mn-Zn(10) |

| Fe-Ni-Si(10) | Fe-Ni-Ti(10) | Mg-Mn-Ni(10) | Mg-Mn-Si(10) | Mn-Ni-Si(10) | Mn-Si-Zn(10) |

| Ni-Si-Ti(10) | Ni-Si-Zn(10) |

Database Validation and Application

The PanZn database is the commercial database for alloy design and processing optimization of Zn alloys. It has been validated by a large amount of experimental data.

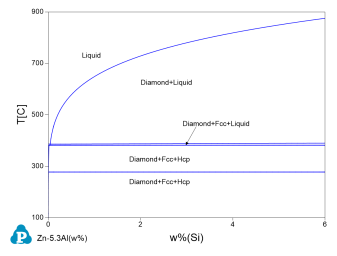

Berent et al [2016Ber]did the thermal analysis and microstructure observation of a serial of Zn-Al-Si alloys. The microstructure shows primary Si particles, Zn+Al eutectic structure and Zn+Al eutectoid structure. Figure 1 shows the calculated phase diagram of Zn-5.3Al-xSi (wt.%) section. The calculated result is in good agreement with their thermal analysis results and microstructure observations.

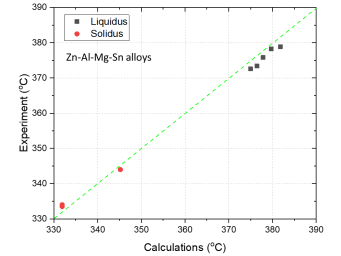

Gogola et al. [2021Gog] measured the liquidus and solidus temperatures of a serial Zn-Al-Mg-Sn alloys. The calculated results using this database is in good agreement with the experimental data as shown in Figure 2.

Figure 2: The comparison of the liquidus and solidus temperature of Zn-Al-Mg-Sn alloys from experiments and calculations

[2016Ber] K. Berent, J. Pstruś, T. Gancarz, Thermal and Microstructure Characterization of Zn-Al-Si Alloys and Chemical Reaction with Cu Substrate During Spreading, J. Mater. Eng. Perform., 25 (2016) 3375-3383

[2021Gog] P. Gogola, Z. Gabalcová, M. Kusý, H. Suchánek, The Effect of Sn Addition on Zn-Al-Mg Alloy; Part I: Microstructure and Phase Composition, Materials (Basel), 14 (2021) 5404.